Main benefits of Secondary Glazing

- Cost Saving

- Energy Saving

- Heat Insulation & Noise Reduction

- Condensation Reduction

MAGNESEALED secondary glazing

It costs around 85% cheaper than your average double glazing installation. It can reduce noise pollution by up to 55% (up to 13 dB reduction when added to existing 4mm single glazing) and outperforms double glazing by up to 10%. This reduction is due to the air space created between the MAGNESEALED glazing panel and the original glass window. This air space creates a baffle, reducing external noises. For acoustic insulation in general, the bigger the gap you can achieve the better, with a 100mm gap being the optimum. While the gap in a 24mm double-glazed unit is a mere 16mm, secondary glazing gives the opportunity for a much larger gap, depending on the specifications of your windows. MAGNESEALED units can also be ordered to a variety of sizes and thickness.

Secondary Glazing

The following materials can be used for secondary glazing:

Acrylic Sheets

Acrylic Perspex Sheets is 8-10 times stronger than glass and has a high resistance to UV rays.

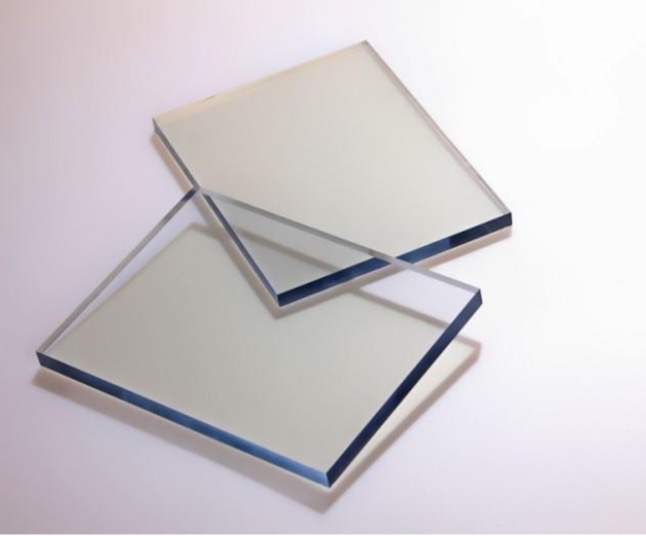

Polycarbonate Solid Sheets

Polycarbonate Solid Sheets can be used instead of Perspex or Acrylic. It offers additional strength (20 times stronger than glass) and also carries a Fire Rating B S476: Part 7

In a controlled test, measuring sash windows facing a busy road before and after the addition of polycarbonate, a 10.4dB reduction was achieved. A 10dB reduction effectively halves the noise level perceived by the human ear.

U Values indicate the rate of heat flow across a material – the lower the value, the better the insulation.

Single glazing has a typical U Value of 6 w/m2k.

Based on scientific evidence the Magnetic secondary glazing system is able to achieve a U value of 2.28w/m2k.

As much as 15% of the heat in a dwelling is lost due to cold air coming in through gaps around the windows. Added to the heat loss through the glass of the window itself and you have a huge potential total loss of 25%.

MAGNESEALED FOR CONSERVATION

The replacement of existing windows with double glazed units can in many cases lead to a change in appearance, particularly the flatness of new glass and the need for thicker timber sections and glazing bars.

In historic buildings, there should be a strong

preference for repair or solution, Rather than Replacement as

the use of double glazing can lead to a loss of

historic fabric, Not to mention losing or throwing away part history of the building, Adding secondary glazing would

often be the preferred option for any conservationist.

In the UK this magnetic system solution was approved by the

English Heritage, or for the Institute of Historic Building Conservation (IHBC).

You may need to apply for planning permission to fit new windows (such as double-glazing) in your flat or maisonette. You will not need planning permission to add internal secondary glazing, as it does not have any interference with the existing original window.

Works to a listed building like (double glazing) that affect its special historic character without consent is a criminal offence.

From the perspective of historic and aesthetic significance, secondary glazing solutions have the advantage over double glazing systems that they are reversible: the window can be returned to its original condition in the future if required.

Magnetic Secondary glazing when carefully measured, designed and installed allows the original windows

to be Retained unaltered, and where necessary Repaired, whilst reducing air leakage

and conducted heat losses. As a result there is no loss of historic fabric and in most

cases the installation is easily reversible.

Energy efficiency in historic buildings.

HISTORIC ENGLAND.

A study commissioned by Historic Scotland looked at the improvements that could be made to a typical sash window to reduce its heat loss.

Magnetic Secondary Glazing against double glazing.

The tests, which were carried out in 2008 at Glasgow Caledonian University, included the original single-glazed window which had been draught proofed using : low-E,

(Slim-profile sealed units because they can be fitted within the glazing bars without obscuring the sight lines & Also a Full Draught proofing brush system.

The findings showed that the chosen secondary glazing system actually outperformed the chosen double glazing system, with a U-value that was more than adequate for current building regulations. Due to the larger air lock cavity that is created between the sash and the room interior fitted magnetic panel. Its cavity is normally around 100mm where as typical double glazing is only 14mm. Not to mention its a fraction of the cost as well.

Cleaning

Both acrylic and polycarbonate are easy to clean. The best choice for cleaning is a micro fibre or 100-percent cotton cloths. Acrylic has a low chemical resistance and needs more specific cleaners. When cleaning acrylic, it is best to use only mild soap and water or a plastic cleaner. Polycarbonate has a higher chemical resistance than acrylic; it can be cleaned by harsher cleaners containing chemicals such as ammonia. Neither plastic should be cleaned with solvents. Durability Both acrylic and polycarbonate are weather resistant and expand and contract with temperature changes without long-term or permanent shrinkage. Both acrylic and polycarbonate can scratch, so wool rags and paper towels, which are made from abrasive binding agents, should be avoided. Acrylic is more likely to chip than polycarbonate because it is less impact-resistant. It does not scratch easily, however, and will not yellow over time. Polycarbonate has low flammability, while acrylic will burn slowly and is not recommended hi areas where flames may be present.

Cost Polycarbonate is more expensive than acrylic. It tends to cost about twice the price of acrylic.